Digital Printing, a revolutionary force in the printing realm, has significantly transformed the traditional printing landscape. Departing from the conventional techniques that rely on physical plates and intricate set - up procedures, it directly transfers digital files such as PDFs and JPEGs onto diverse materials including metal, glass, and plastic. This innovation offers remarkable flexibility, being highly suitable for short - run jobs, which cuts down costs for small - scale projects. Digital printing also excels in speed, eliminating time - consuming steps like plate - making and calibration, thus being able to quickly initiate the printing process, a great advantage for time - sensitive tasks. In terms of quality, it now rivals traditional methods with high - resolution, vivid prints and accurate color reproduction. Its applications span across commercial printing, packaging for creating small - batch unique designs, and the art field for precise reproductions. With its flexibility, speed, quality, and customization capabilities due to advanced color management systems and precise inkjet technology, Digital printing has revolutionized the printing industry and is set to have an even greater impact as technology continues to advance.

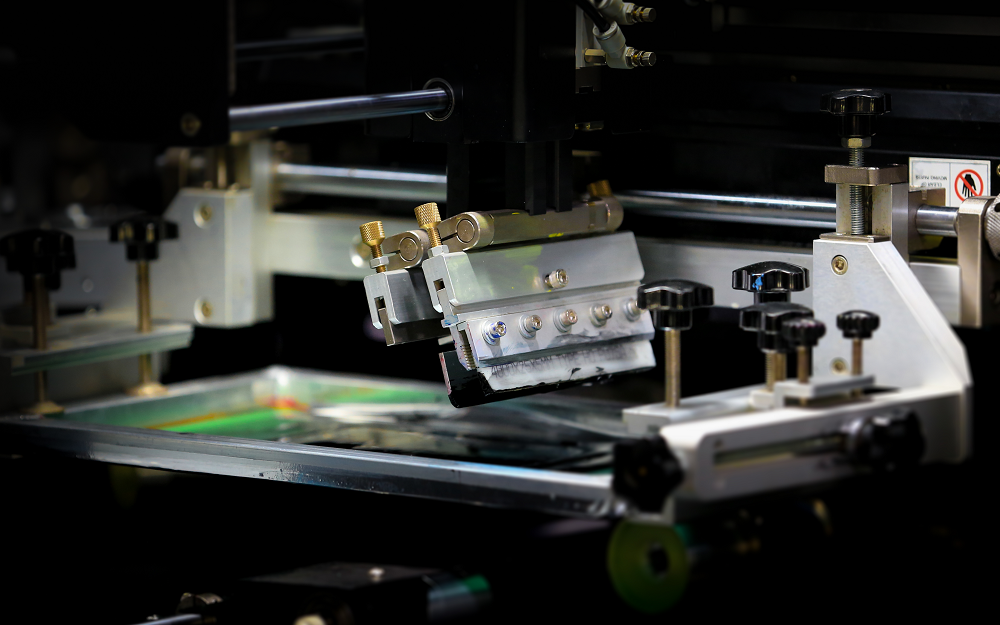

Screen Printing is a traditional and versatile printing technique that has been widely used for decades. In this process, a mesh screen is used as a stencil. Ink is forced through the open areas of the screen onto the substrate, which can be various materials and shapes like glass, plastics, metal and ceramics. First, the image to be printed is created on the screen by blocking off the non - printing areas with a light - sensitive emulsion. Once the screen is prepared, ink is poured onto the screen and spread across it using a squeegee. This method is highly suitable for large - scale printing jobs due to its relatively simple setup and the ability to reproduce the same design consistently. It offers excellent color opacity, making it ideal for creating bold and vibrant prints. Whether for commercial or artistic purposes, screen printing remains a popular choice in the printing industry.

Digital Printed Relief is an innovative printing technique that combines digital technology with the creation of relief - like textures and patterns. By precisely controlling the deposition of inks or special materials through digital means, it generates raised or recessed elements on the printed surface. This process allows for highly detailed and customized relief designs, which are difficult to achieve with traditional methods. It offers flexibility as digital files can be easily adjusted. Digital printed relief is increasingly used in various fields, such as in the production of luxury packaging to add an elegant tactile touch, and in art prints to create unique three - dimensional visual effects, enhancing the overall aesthetic and value of the printed items.

Hot Stamping is a classic and widely - used printing technique that adds a touch of elegance and distinction to printed materials. The hot stamping process is a printing technique that applies a metallic foil onto a surface using heat and pressure. This technique is commonly used to create decorative accents or logos on various materials. For glass, need to screen print primer first, then stamping by silicone roller, the foil was transferred onto primer, not directly to glass. For plastic, begins by creating a die or mold of the desired design, which is usually made of brass or magnesium. The die is heated and pressed onto the material, transferring the foil onto the surface. Hot stamping offers excellent durability and resistance to wear, making it ideal for applications where long - lasting and visually appealing finishes are required.